formula for calculating work in progress inventory

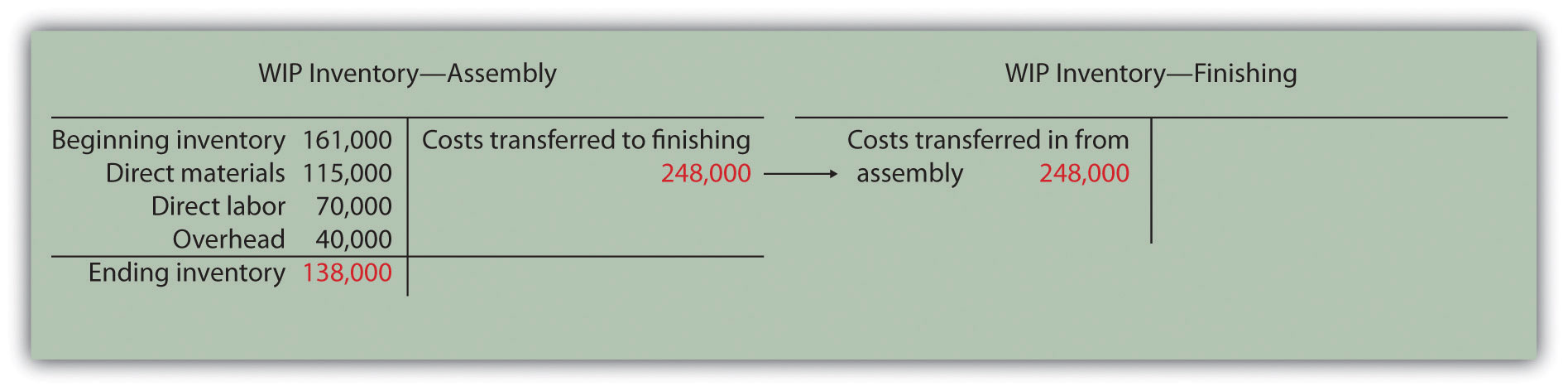

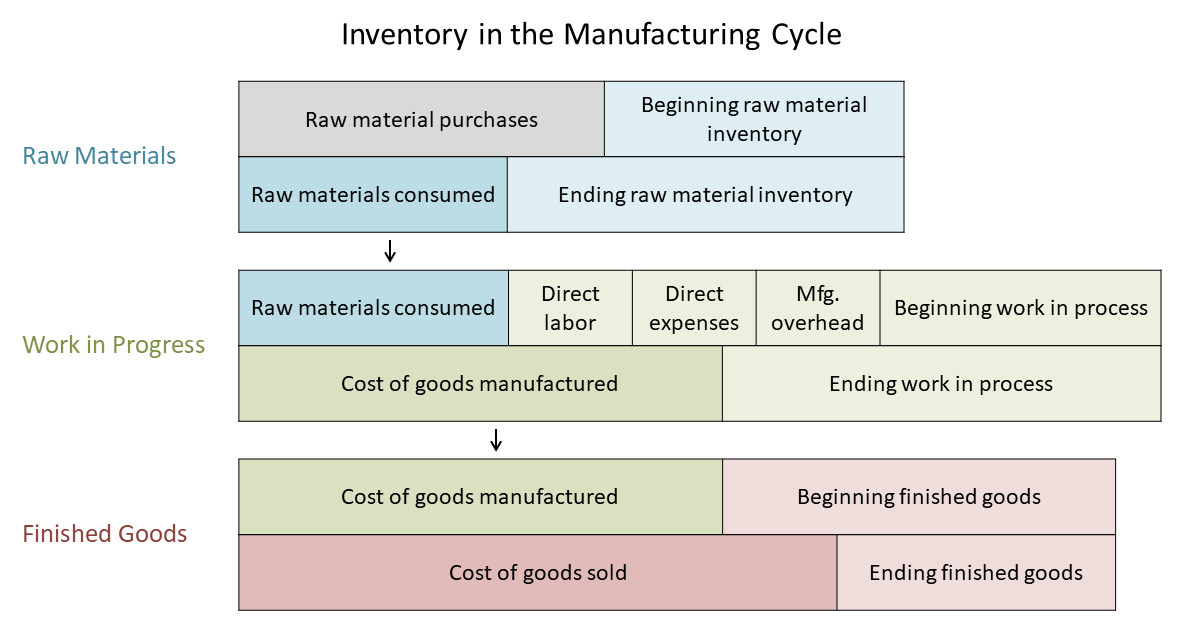

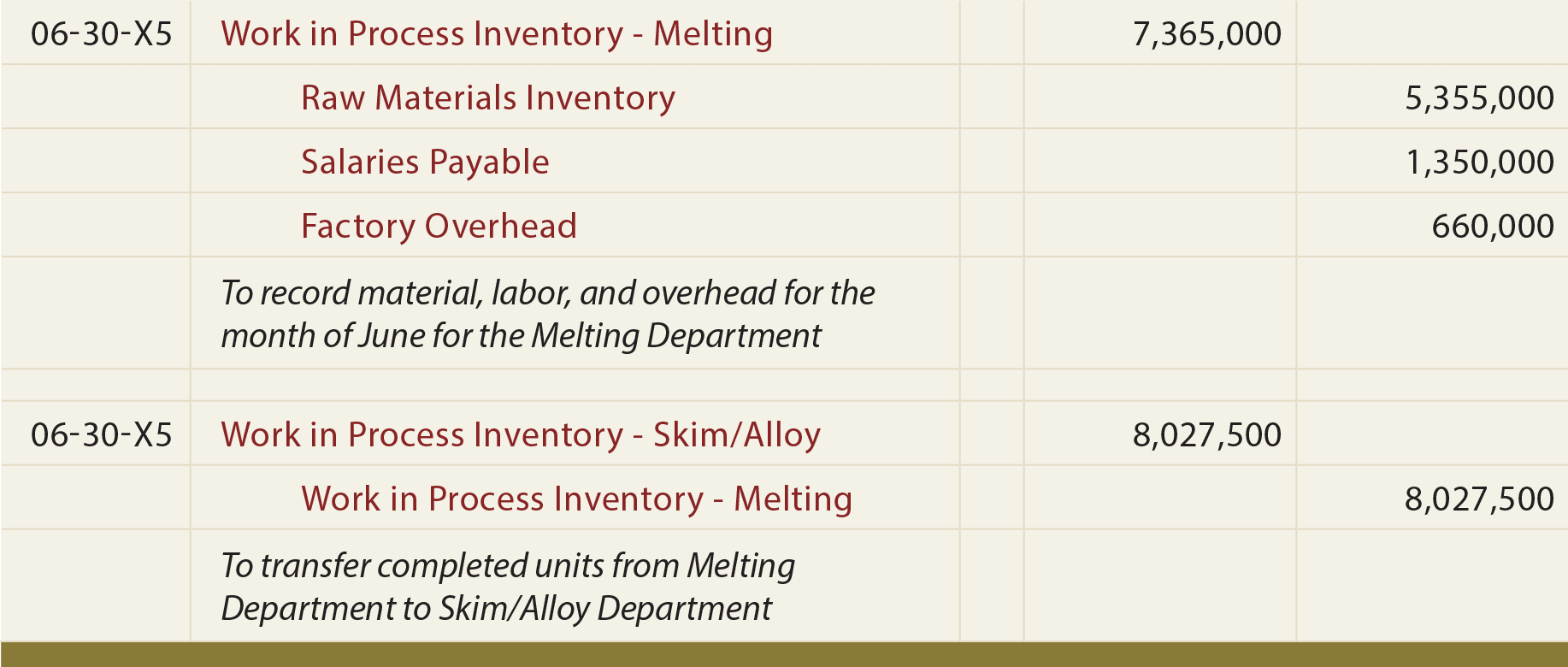

If you know the total manufacturing cost for both processes you can then calculate the value of work in progress after stage 1. Work in Progress Inventory Formula Initial WIP Manufacturing Costs Cost of Goods Manufactured The purpose of the WIP is to figure out the production cost at each stage of the process.

Wip Inventory Definition Examples Of Work In Progress Inventory

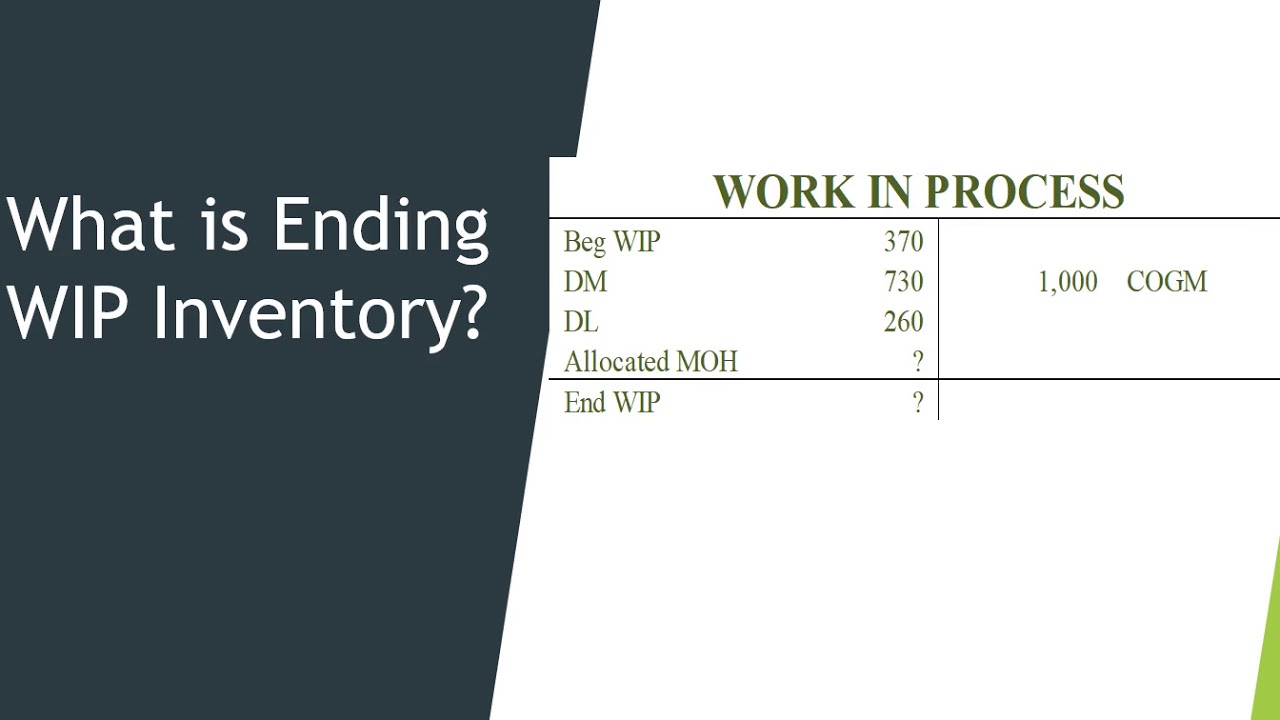

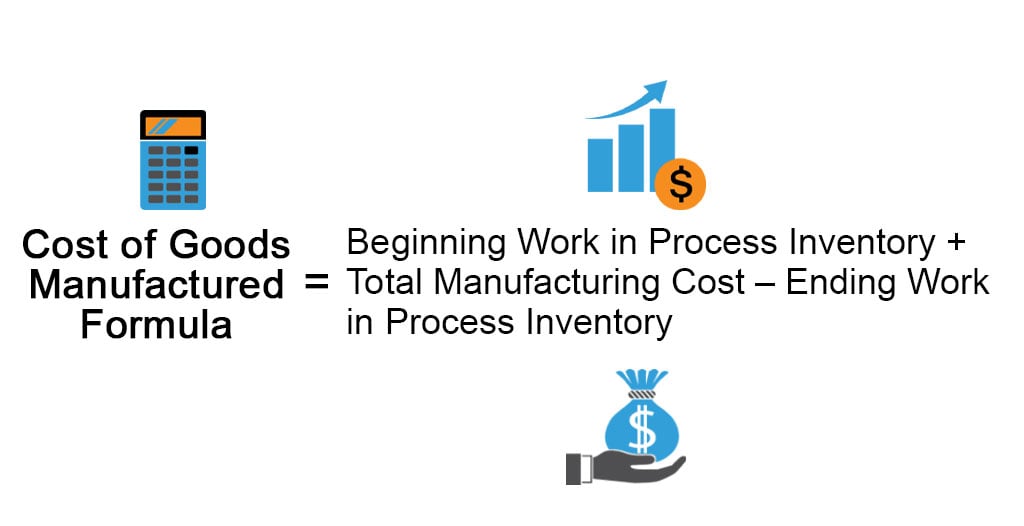

Work in Process Inventory Formula Therefore the formula from which a business can calculate their COGM using work in process inventory costs can be displayed like this.

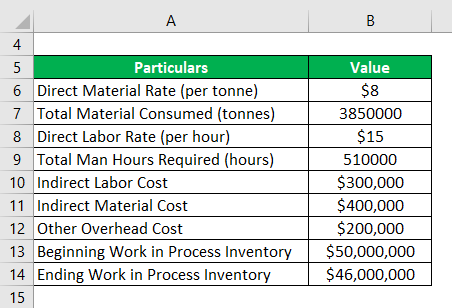

. Considering that it takes two weeks to make a widget. The formula is as follows. 10000 300000 250000 60000 Work in process inventory 60000 The WIP figure indicates your company has 60000 worth of inventory thats neither raw material nor finished goodsthats your work in process inventory.

Under this method it is assumed that value of opening WIP is merged with the. It consists of items that are yet to be. How Do You Calculate Work In Process Inventory.

Has a beginning work in process inventory for the quarter of 10000. The value of that partially completed inventory is sometimes also called goods in process on the balance sheet particularly if the company is manufacturing tangible items rather than providing services. Wise optimizes all aspects of the business process improving efficiency accuracy.

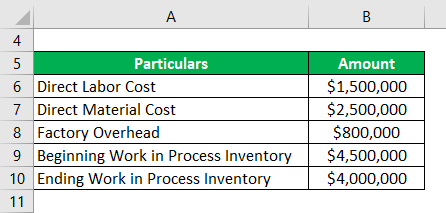

Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs- Ending WIP Inventory Work In-process Inventory Example Assume Company A manufactures perfume. Total Cost of Manufacturing Beginning Work in Process Inventory Ending Work in Process Inventory Cost of Manufactured Goods. Your WIP inventory formula would look like this.

There are things it doesnt consider like waste spoilage downtime scrap and MRO inventory. Adding the totals of these categories will give you your current work in process inventory. Then for one batch that has completed stage 1 its value is 4000 40 x 10000.

Starting work in progress WIP inventory manufacturing costs - the cost of manufactured goods COGM While formulas are nice its better to have an actual example with real numbers to show you how this plays out in practice. Inventory control for growing SMB distributors manufacturers online retailers. How to Calculate Ending Work In Process Inventory The work in process formula is.

The work in process formula is expressed as. Keep in mind this value is only an estimate. So lets say a company produces candles.

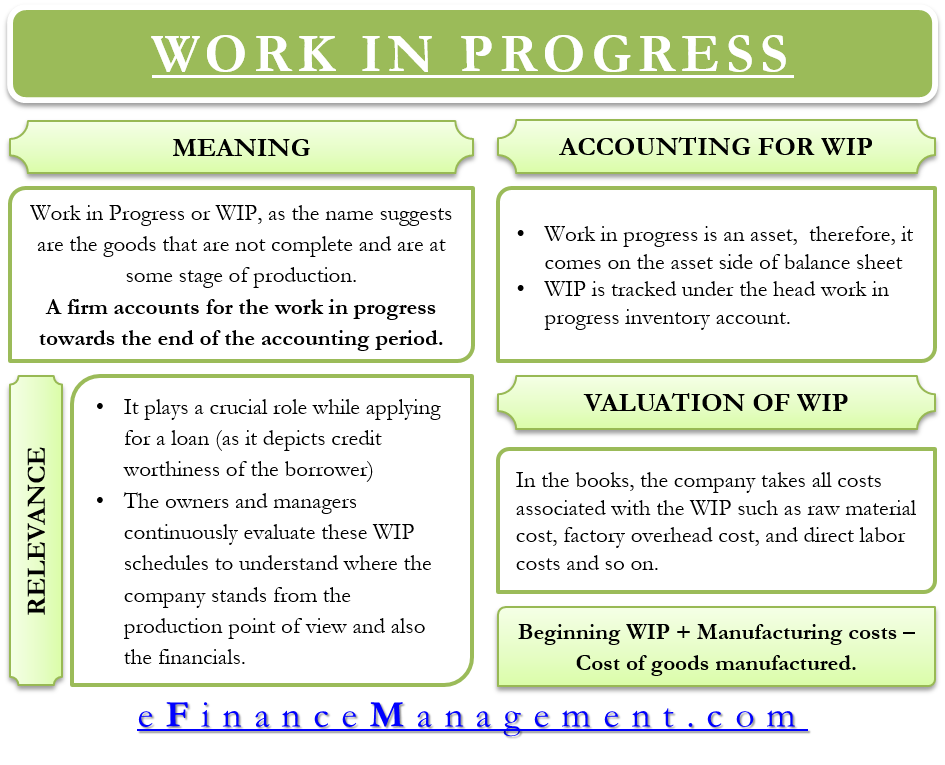

Formula and Calculation of WIP Inventory. WIP Work In Process Inventory is the total cost of unfinished goods currently in the production process. The revenue is recognized yearly as a percentage of work completed during that year.

Another method that could be used is simply adding up. Beginning WIP inventory Materials purchased Materials transferred to production 2. Under this method average unit cost is ascertained taking the total value of opening WIP value plus costs incurred during the current accounting period.

Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs - Cost of Finished Goods Lets use a best coffee roaster as an example. Use the work in process formula to get an accurate estimate. COGM is important because its the last element youll need to calculate the WIP inventoryCOGM is calculated by adding the first two elements the beginning Work-in-Progress inventory cost and the manufacturing costsAfter adding the two.

Beginning WIP Manufacturing costs - Cost of goods manufactured Ending work in process Example of the Ending Work in Process Calculation. Ad The leading inventory management software for small business. Find the manufacturing costs.

The last quarters ending work in process inventory stands at 10000. WIP or work in process inventory refers to the total cost of unfinished goods currently still in production. The effect of this is that both WIP and completed units are valued at average unit cost.

Unlike just manufacturing costs the cost of manufactured costs is the entirety of costs incurred in making a final product. And this excludes the value of raw materials. Imagine BlueCart Coffee Co.

For example total manufacturing costs for both processes is 10000 per batch. To calculate your in-process inventory the following WIP inventory formula is followed. Let us take a company ABC which manufactures widgets.

If you have a WIP inventory it is usually considered an asset. Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory What Does Work In Process Inventory Mean. The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity.

The WIP Inventory Work-in-Progress cost is a bit more intricate than determining the cost of. The work-in-progress balance represents all the costs of production that are incurred for partially finished goods. Work in process inventory includes all raw goods production expenses and labor costs associated with producing merchandise inventory.

Work in process operating inventory goods in process raw materials used during the period direct labor during the period factory overhead for a period ending inventory. Free Product Tour Available. The beginning WIP inventory cost refers to the previous accounting periods asset section of the balance sheet.

Find the beginning work in progress WIP inventory Start by subtracting the materials transferred to production from the materials purchased to find the beginning WIP inventory. The ending WIP beginning WIP manufacturing costs - cost of goods produced This represents the value of the partially completed inventory which accounts for only a part of what the company will actually produce. Percentage of Work Completed Actual Costs till Date Total Estimated Costs 2 Earned Revenue to Date.

WIP inventory is a component of the inventory asset on the companys balance sheet. Beginning WIP inventory formula. As per the Merriam-Webster dictionary Work-in-process WIP refers to a component of a companys inventory that is partially completed.

The calculation of ending work in process is. WIP is calculated as a sum of WIP inventory total direct labor costs and allocated overhead costs. Revenue to be recognized Percentage of Work Completed in the given period Total Contract Value read more to date.

It is a common term used in the production and supply chain management of e-commerce businesses that manufacture their products. The formula for the same is. Ad Cloud or On-Premise Solutions to Improve the Total Condition of the Supply Chain.

All You Need To Know About Wip Inventory

Work In Process Inventory Formula Wip Inventory Definition

Cost Of Goods Manufactured Formula Examples With Excel Template

How To Calculate Manufacturing Work In Progress Wip Solutionbuggy

Work In Progress Meaning Importance Accounting And More

Work In Progress Wip Definition Example Finance Strategists

Work In Process Wip Inventory Youtube

Cost Allocation To Completed Units And Units In Process Principlesofaccounting Com

Cost Of Goods Manufactured Formula Examples With Excel Template

Work In Progress Wip Definition Example Finance Strategists

Cost Of Goods Manufactured Formula Examples With Excel Template

How To Calculate Finished Goods Inventory

Work In Progress Calculation Of Work In Process Inventory

What Is Work In Process Wip Inventory How To Calculate It Ware2go